.

Asphalt Plant

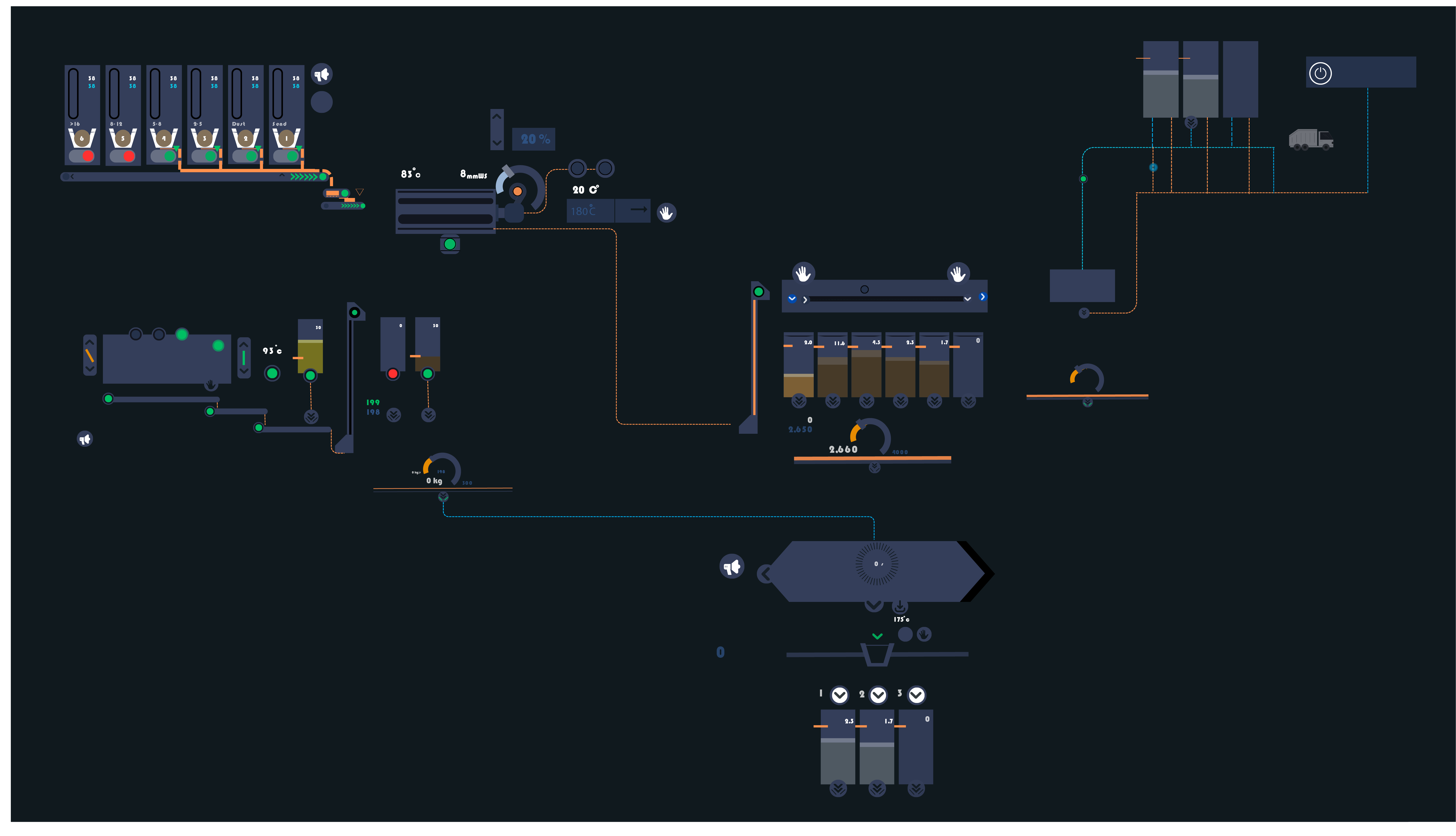

Our company's Asphalt Batch Mix system utilizes state-of-the-art PLC technology that incorporates a comprehensive Individual SCADA System to unify all batching functions into a single integrated controller. This technology allows for real-time batching control on a PLC and a single PC. The Windows-based user-friendly system is designed to quickly teach new operators. The Asphalt Batch Mix Plant can be monitored and operated from two locations, ensuring smooth, uninterrupted production. The system provides warning alarms and fault history. Recipes can be configured based on batch requirements for efficient production. Every component of the plant can be operated manually and controls can be customized to your specific plant needs. This fully interlocked system complies with all safety standards for the global market, preventing accidents and lost time.

The benefits of using Asphalt Batch Mix SCADA are numerous. This system monitors and controls the processes, ensuring consistent performance. All operations can be controlled from a single central location, which reduces the need for a labor force, as the system is fully automated, and improves quality to high standards. Asphalt Batch Mix SCADA stores all data in its database server, allowing future access for performance assessment. Site engineers or construction managers can control all processes from a centralized location.

Transporting bituminous mix from the plant to the site can be challenging due to temperature variations. However, the Asphalt Batch Mix SCADA system solves this problem.